Industrial Solution

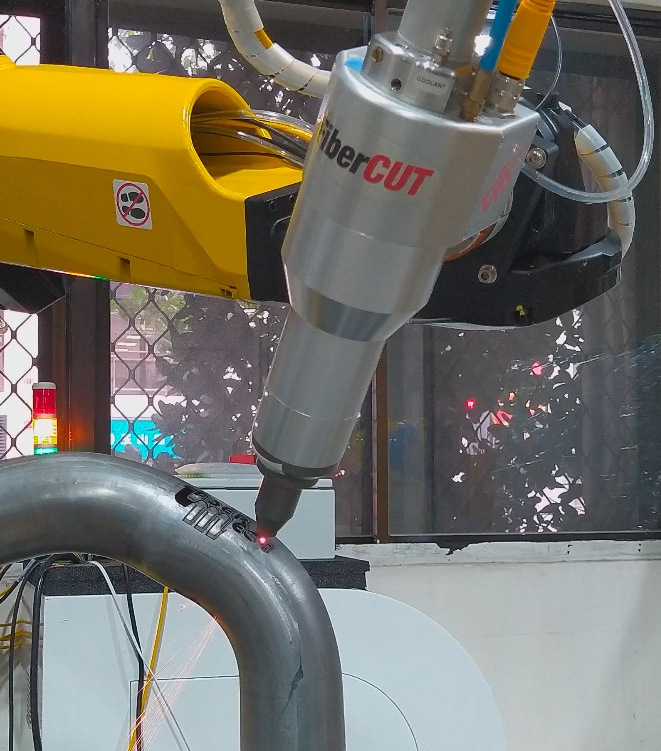

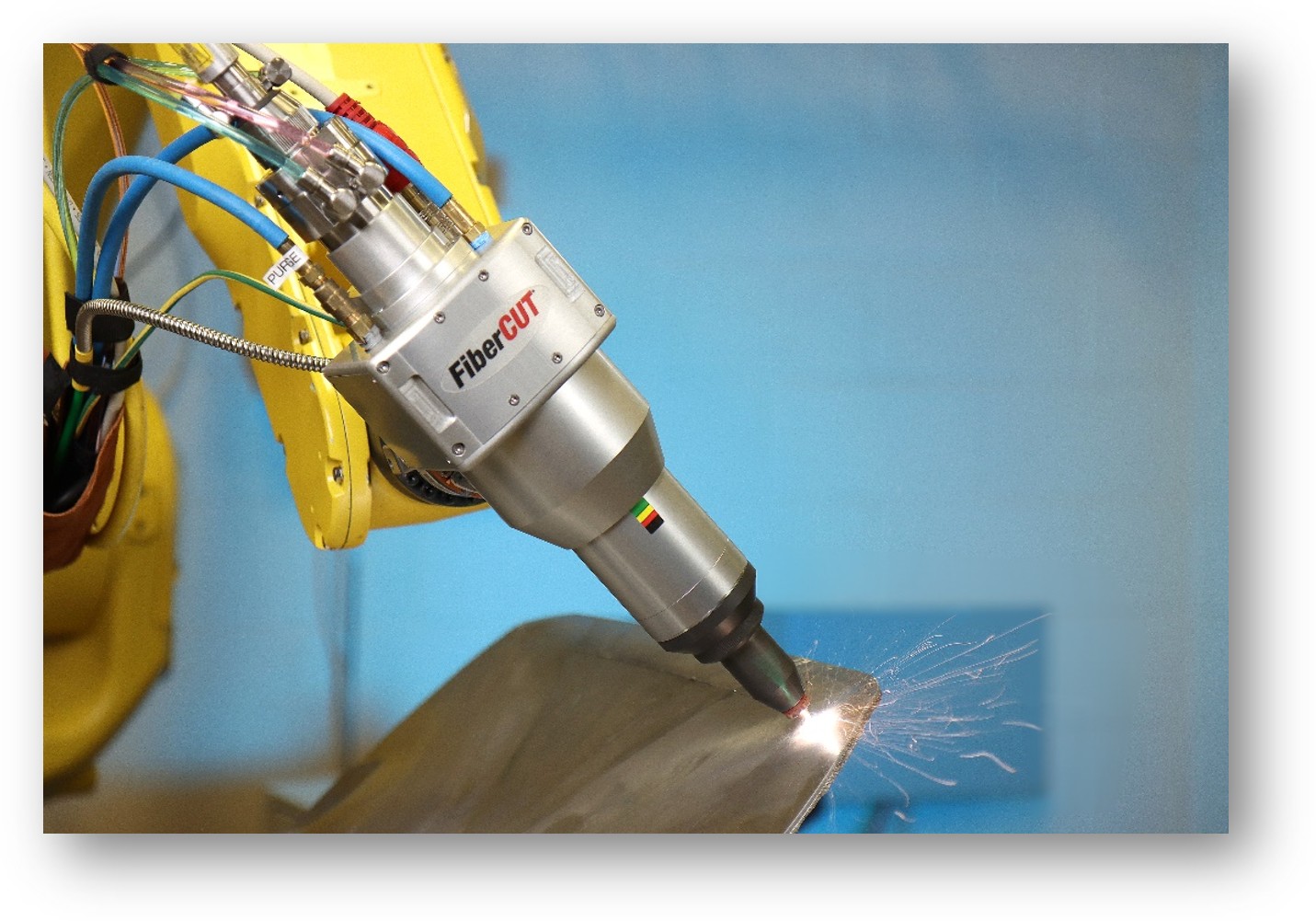

3D Robotic Cutting System

Custom robot-integrated laser cutting for precise, clean cuts on complex 3D parts—efficient for both small and large-scale production, including hard materials like aluminum and boron steel.

High efficiency, flexible solutions, and ultimate precision.

Flexible Integration – Customized Systems Tailored to Your Needs

Our 3D laser cutting systems can be scaled according to your production line requirements, ranging from basic robotic laser setups to fully automated processing systems, with solutions available to meet every demand.

Standard Configuration

Each system includes the essential components required to initiate cutting:

No matter the metal type, thickness, or length,LMT offers the most versatile range of processing heads to suit your needs!

Weighing only 3.5 kg, it effectively reduces inertia transmission to the robot’s supporting arm, enhancing overall motion stability. Suitable for laser systems with power up to 4000W, it is equipped with a sensor-enabled nozzle that detects the proper distance to the workpiece and automatically maintains a stable processing distance via a built-in Z-axis drive system.

Weighing only 3.8 kg, it effectively reduces inertial transmission to the robot’s supporting arm. It supports laser systems with up to 6000W power and features a nozzle that can automatically sense height and maintain the optimal distance from the workpiece, stabilized by a built-in Z-axis drive system. With up to 30mm of programmable adjustment (from the focal point to the nozzle tip), it enables precise cutting of materials with varying thicknesses and delivers the fastest drilling performance.

Capable of laser drilling holes in any shape, this technology achieves a higher level in cutting irregular materials. Its speed is four times faster than the traditional combination of robotic arms and laser heads, with precision doubled, significantly reducing the cycle time for laser cutting and trimming operations. It delivers cutting performance comparable to five-axis machining centers at a relatively lower cost! Weighing less than 17 kg, it is easier to mount on robotic arms and is ideal for drilling applications on pipes and sheets.

Expand the following automation and safety equipment according to your production process requirements:

.JPG)

.JPG)

Contact us to consult on professional laser solutions that bring efficiency, flexibility, and superior quality to your production—helping you reach the next peak in manufacturing!

| Part | Specification |

| Cutting System | 2 kW - 6 kW |

| Fiber Laser | Optional |

| Cooling System | Optional |

| Crash Protection Device | Optional |

| Cutting Head | Laser Mech Cutting Head |

| Gas | Optional |

| Cutting Head Moving Device | ABB IRB 2400 6+1 axis, Fanuc M20iB, M20iD, 800i |

| Positioning Device | Optional |

| Contaol Panel | LMT Configuration |

| Power Meter | Optional |

| Cutting Zone and Workpiece Handling Robot | Customized integration |

| Handling Robot | Customized integration |

| Working area | Customized integration |

| Accuracy | Customized integration |

| Repeatability | Customized integration |

| Enclosure | Client-side Handling |

| Electrical Specifications | 40 kVA |

| Installed Power | 400-480 V/3P + PE @ 50-60 Hz |

| Control | SIEMENS |

| Operating Interface | System Configuration |