Industrial Solution

Additive Manufacturing

Large-scale Metal Additive Manufacturing

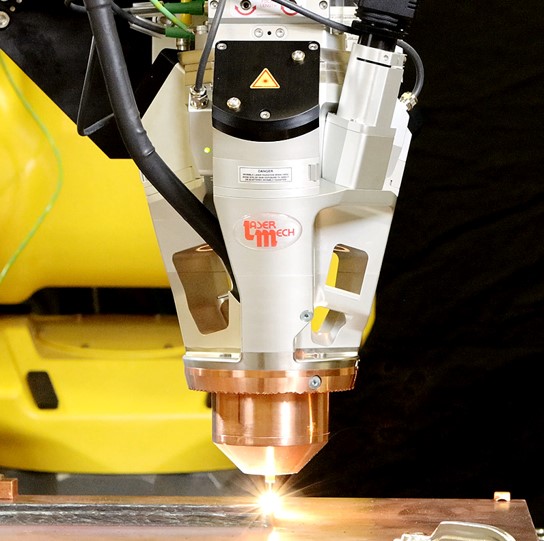

Laser Mechanisms’ laser-based central wire feed additive manufacturing technology offers a faster, cleaner, and more cost-effective production method for creating large and complex metal components.Whether for small-batch production or large-scale manufacturing, it flexibly adapts to your project needs—making even the most demanding requirements possible!

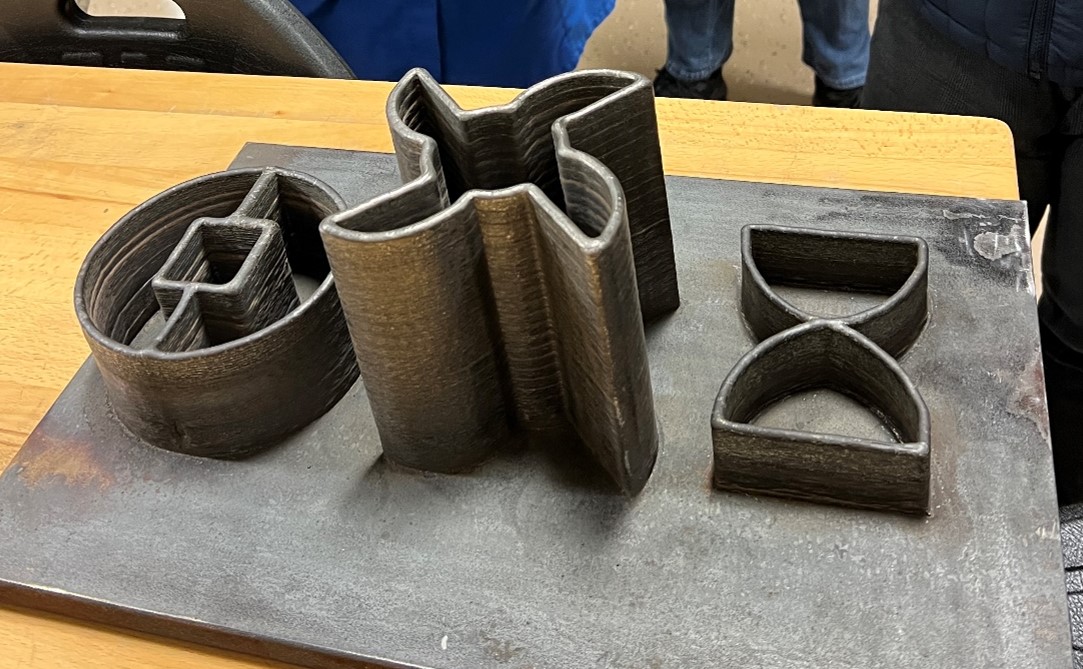

Large-Scale Component Printing – Bringing Bigger Visions to Processing

This system enables the direct manufacturing of large-scale metal components with virtually no size limitations. It forms complete, integrated structures without the need for cutting or welding, eliminating concerns about structural integrity typically associated with post-processing.

Speed & Productivity

- ➤ Compared to the typical market rate of 1–2 kg/hour, aser Mech’s cladding head achieves speeds of 5–15 kg/hour, executing your designs with ultra-high efficiency. This dramatically reduces production time—by up to 10 times—while maintaining exceptional build quality.

- ➤ Supports 24/7 operation for uninterrupted production efficiency.

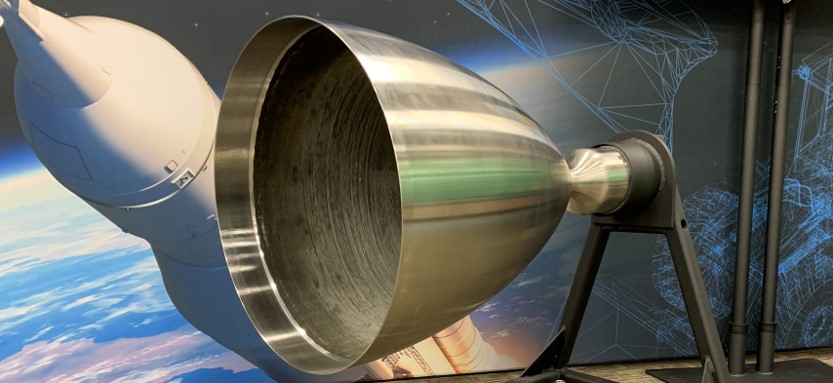

- ➤ Example – Rocket Nozzle

- Total Manufacturing Time: 20 Hours

-

Deposition Rate: 1.8 kg/hour

Material Used: Duplex Stainless Steel

Material Efficiency and Cost Savings

- ➤ Exclusive central feeding technology maximizes material utilization, minimizing waste and excess.

- ➤ Capable of processing high-performance materials such as titanium, nickel alloys, duplex stainless steel, and carbon steel.

- ➤ Significantly reduces energy consumption compared to casting and forging.

- ➤ Reduces production cycles from months to hours.

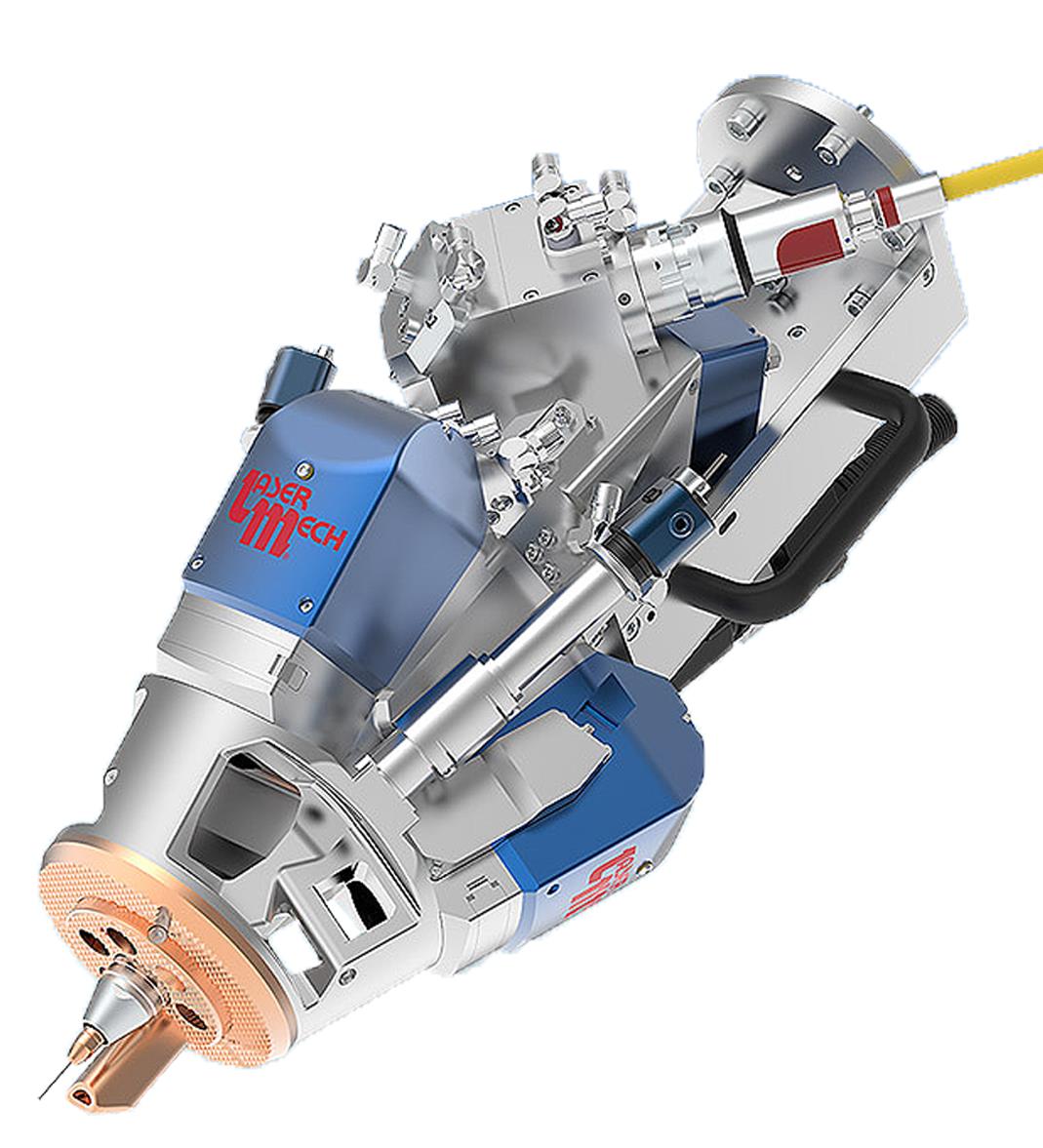

The perfect blend of precision and stability.

- ➤ Laser hot wire technology delivers high-strength, high-quality welding and dense structures.

- ➤ Real-time monitoring of heat input, wire feed speed, and overall stability ensures consistent quality with minimal defects.

- ➤ Integrated software provides comprehensive control over geometry, process parameters, and production workflow.

-

Application - ➤ Aerospace Industry: High-Performance Structural Components

- ➤ Defense Industry: Large-Scale and Custom Strategic Components

- ➤ Automotive Industry: Vehicle Body Structures and Engine Components

- ➤ Shipbuilding and Marine Industry: Large-Scale Corrosion-Resistant Components

- ➤ Mining Industry: Heavy-Duty Custom Components

- ➤ Construction Engineering: Custom Steel Structures and Reinforcements

- ➤ Petrochemical / Oil Industry&Natural Gas Industry: Corrosion-resistant and pressure-rated critical components