Industrial Solution

Next-Gen Laser Processing Cell

%20_Fin.jpg)

Advancing Precision Laser Processing Beyond Limits

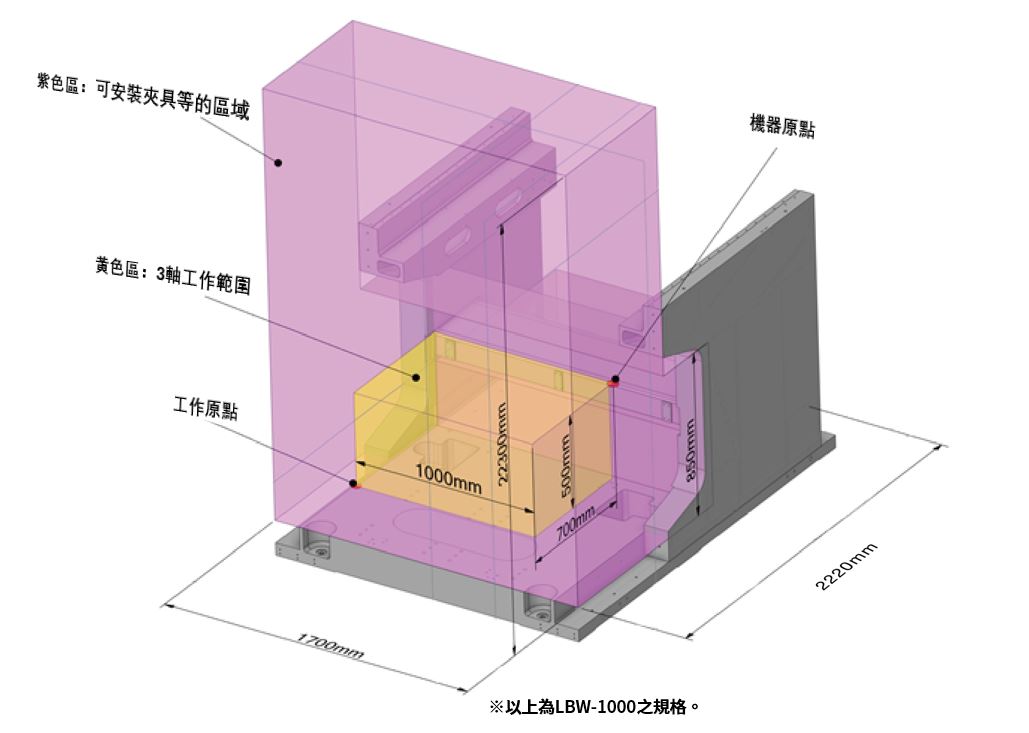

The LBW Next Gen laser system is a fully integrated processing unit engineered for cutting-edge industrial applications. From welding and cutting to other precision tasks, the LBW series delivers unmatched stability, efficiency, and complete control—providing smart, high-quality laser performance every time.

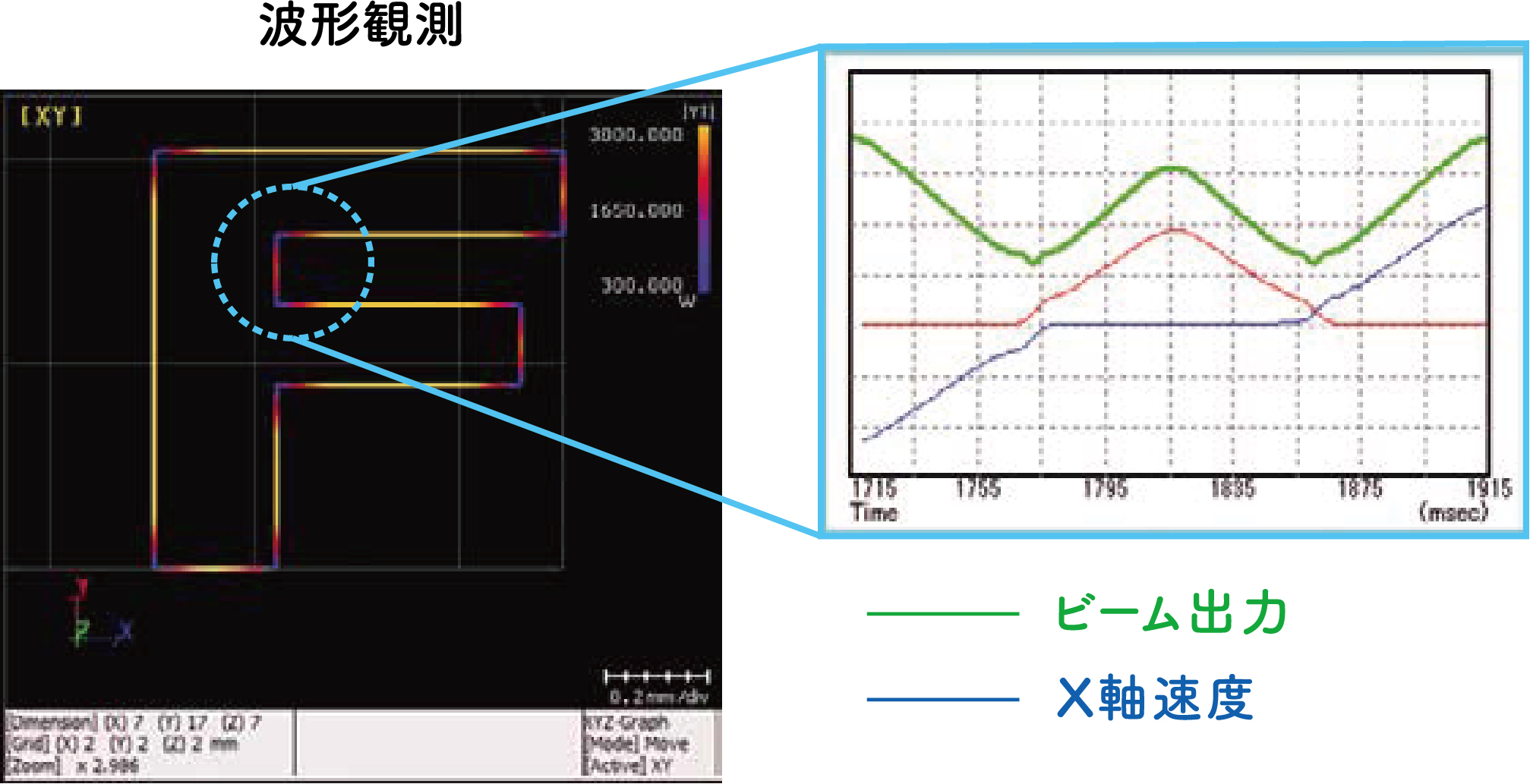

Achieve high-speed and efficient 3D machining with 4-axis synchronized control.

Laser output timing and power are precisely synchronized with 4-axis motion control, minimizing overlap and end zones while maintaining high processing quality.

2. High-rigidity structure enables high-speed, high-precision, and high-quality processing.

Engineered for stability under vibration, thermal changes, and dynamic loads, our structure leverages Finite Element Method (FEM) analysis to consistently achieve high-precision and high-quality results.

By relocating the linear guide to the upper section of the machine, durability is enhanced, maintenance intervals are extended, and the frequency of parts replacement is significantly reduced. A localized dust collection system is installed near the keyhole area to efficiently remove smoke and particles generated during processing. The high-rigidity machine frame also supports precision micro-processing with a single-mode laser beam.

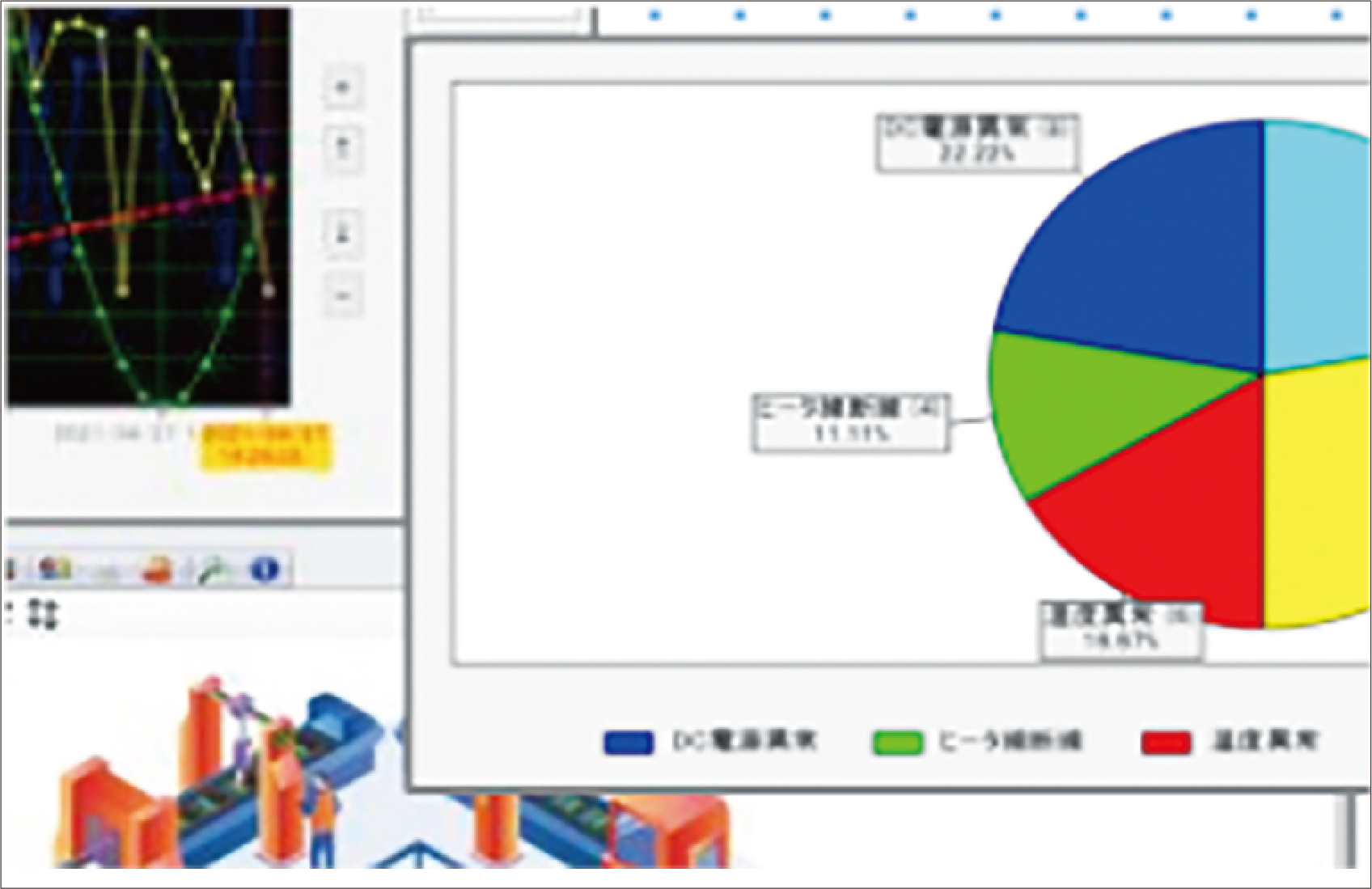

3. Real-time monitoring of processing data ensures optimal equipment uptime and operational efficiency.

Recording Function (Standard Feature)

Recording Function (Standard Feature)

PCP (Process Control Platform) enables time-sequence data collection from the prototyping stage, allowing production conditions to be directly applied to mass production, greatly improving efficiency.

Expansion Functions (Optional)

Expansion Functions (Optional)

Functions such as remote maintenance, graphical monitoring, alarm supervision, and remote operation further enhance the efficiency of equipment management.

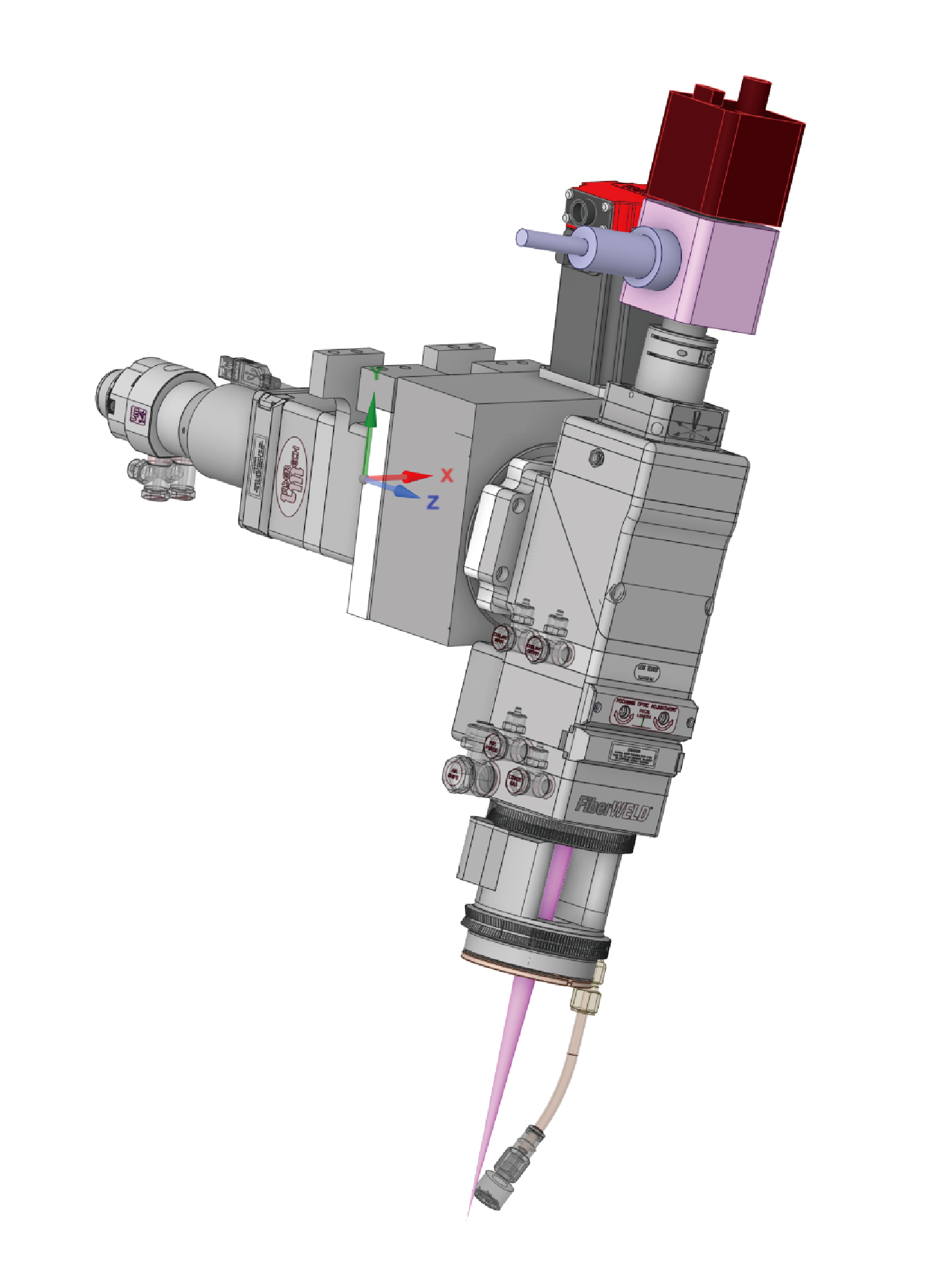

4. A variety of optional processing heads are available to accommodate different workpiece requirements.

Rotary Processing Head:

±140°The servo-driven rotary mechanism enables dynamic angle adjustments, enhancing flexibility and reducing overall processing cycle time.

3D Cutting Head:

Featuring a high-speed response nozzle to ensure stable and precise cutting of intricate 3D structures.

Scanner:

Supports synchronization with CNC systems to enable high-speed and highly efficient laser processing.

Multi-head Configuration

Enables concurrent machining of multiple workpieces, significantly boosting overall manufacturing productivity.

Our Service

01. Concept Planning and System Design

01. Concept Planning and System Design

We collaborate closely with you to develop a comprehensive system concept and deliver customized solutions tailored to your application requirements.

02. System Manufacturing and Delivery

02. System Manufacturing and Delivery

We manage the entire process from design to assembly and manufacturing, ensuring on-time and seamless delivery.

03. Quality Verification and Startup Support

03. Quality Verification and Startup Support

We provide on-site installation and thorough testing to guarantee stable and reliable system performance.

04. After-Sales Technical Support

04. After-Sales Technical Support

We provide comprehensive long-term technical support and maintenance services, ensuring worry-free operation and lasting reliability.

| Standard Feature | |||

| No. o f Driving Axess | 4 axis | LBW-1000 | LBW-500 |

| Travel Distance | X-axis | 1000mm | 500mm |

| Y-axis | 700mm | ||

| Z-axis | 500mm | ||

| B-axis(Θ) | ±140° | ||

| Travel Speed | X/Y/Z-axis | 40m/min | |

| Rotating Speed | C-axis | 200rpm*2 | |

| B-axis(Θ) | 100rpm | ||

| Positioning | Repeatability (XY Z) | Each Axis 0.01 mm or lower | |

| Repeatability (Θ、C) | 60 arc.sec. or lower | ||

| Main Controller(CNC) | FANUC Series 0i-LF Plus | ||

| Max. No . of Controlled Axes:7 (2 systems:9 axes) | |||

| No. of Simultaneously Controlled Axes:4 | |||

Interested in learning more? We’d be glad to engage in a detailed discussion with you.