Industrial Solution

LDD Real-Time Laser Weld Measurement

LDD — Setting a New Standard for Intelligent Weld Quality Monitoring

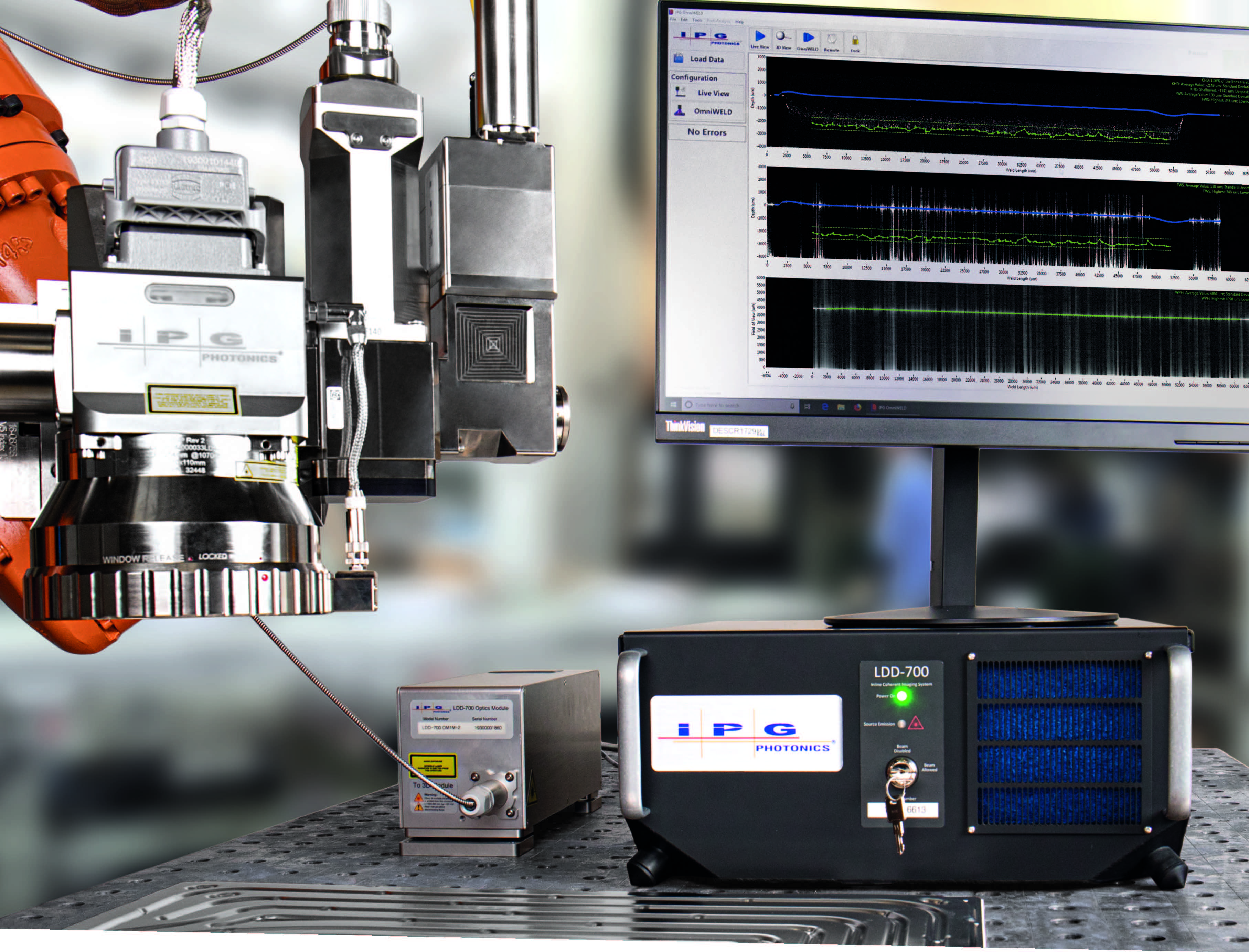

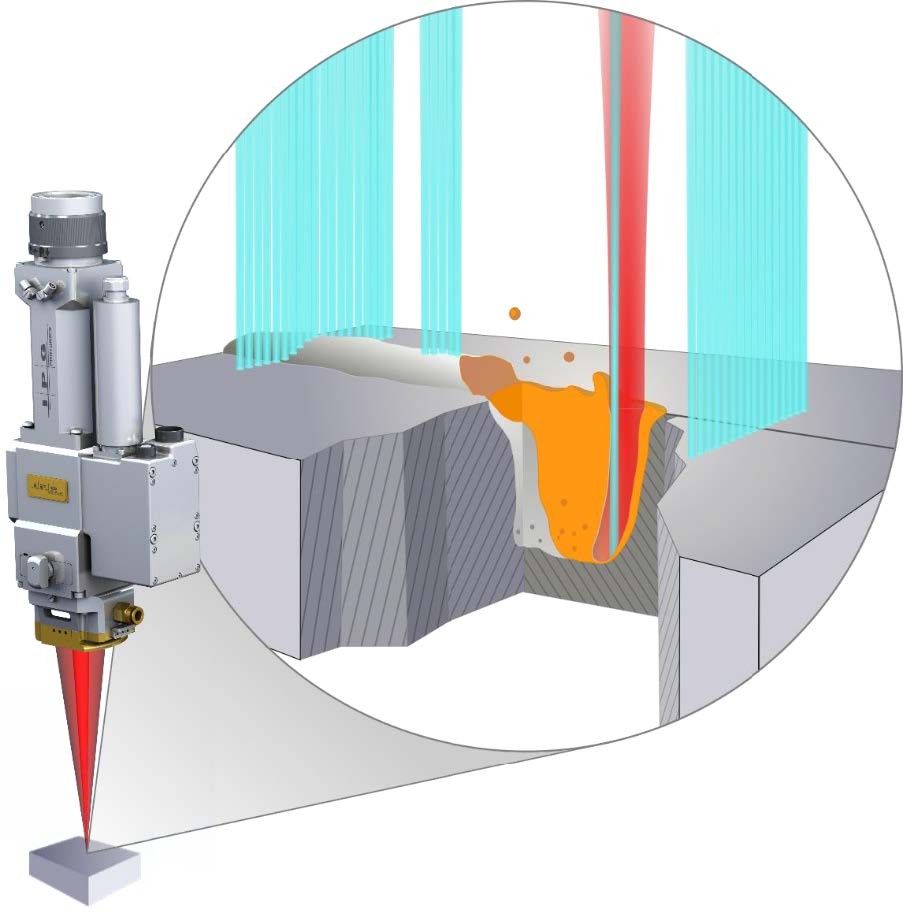

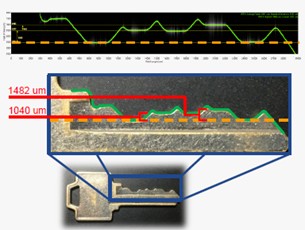

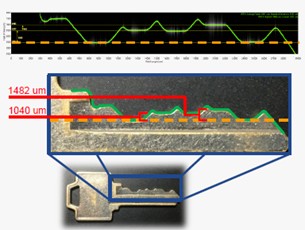

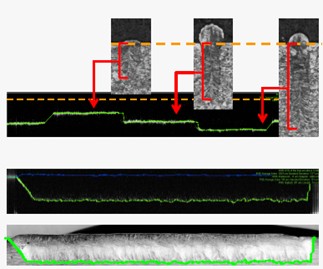

💡 Achieving greater precision, higher efficiency, and smarter performance.——The LDD-700 stands as the industry's only system offering real-time weld depth measurement through advanced optical interferometry. (Interferometry-based measurement), LDD-700 is the industry's only system capable of real-time weld depth measurement, utilizing optical interferometry technology. It provides 100% in-process inspection for every weld, ensuring consistent quality, reducing defect rates, and enabling smarter, more reliable production.

Designed for high-quality welding applications across aerospace, defense, shipbuilding, battery production, automotive, medical devices, and other mission-critical structural welds.

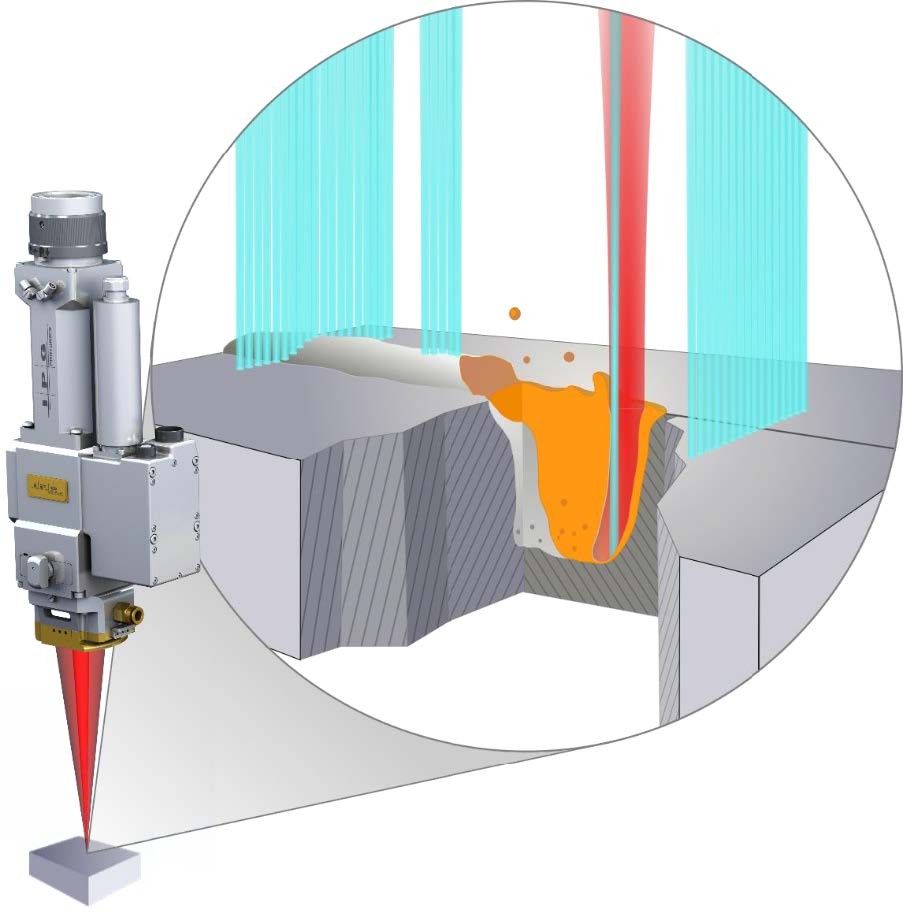

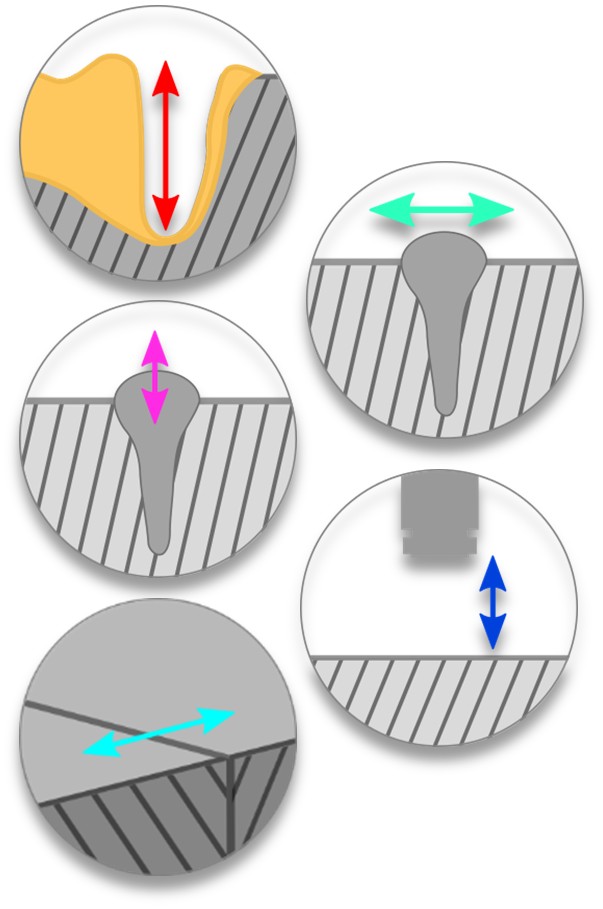

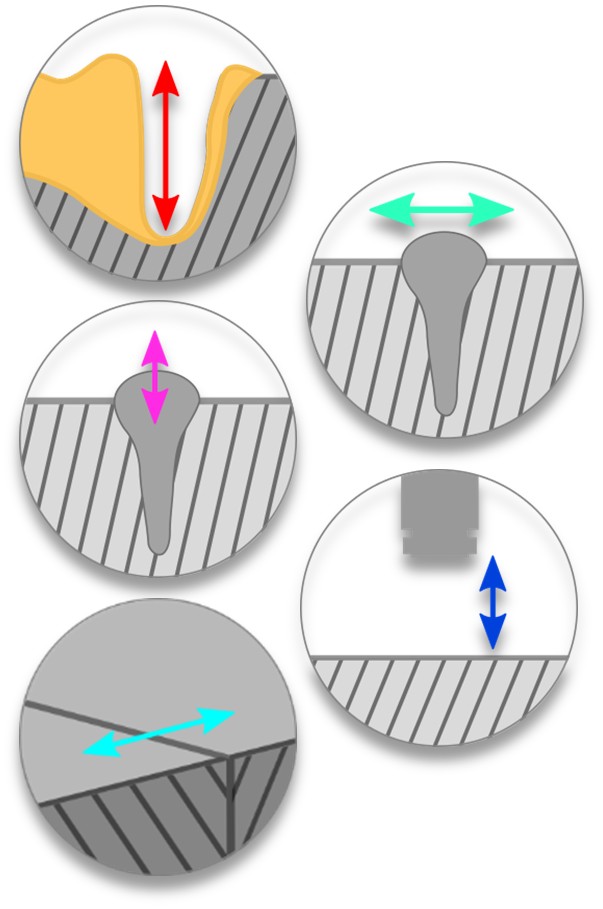

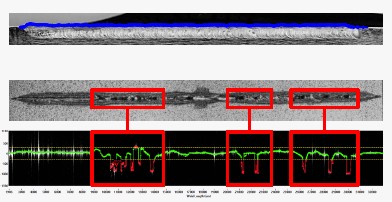

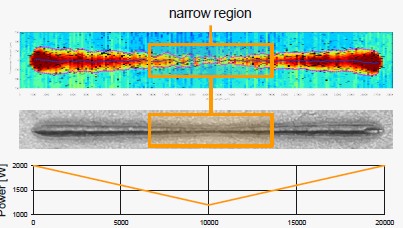

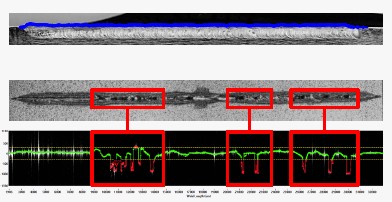

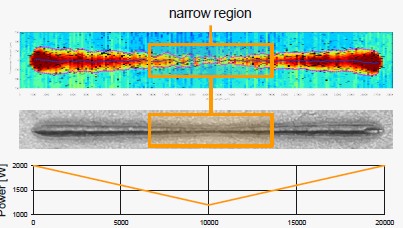

Real-time monitoring ensures every weld is flawless, with over 20 key parameters measured throughout the welding process—before, during, and after—to verify seam positioning, weld depth, fusion condition, and surface quality.

By enabling automated inspection and real-time corrective actions, the system reduces scrap rates, minimizes cost waste, and ensures only defect-free components enter the market.

A smart welding solution built for Industry 4.0, seamlessly integrating with production lines to capture and analyze comprehensive welding data—ensuring end-to-end automated quality control and traceability.

How Does the LDD Improve Production Efficiency?

How Does the LDD Improve Production Efficiency?

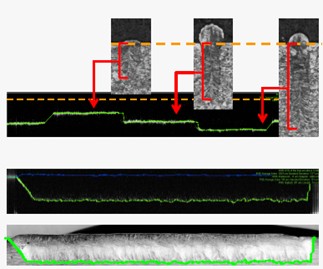

Pre-Weld: The system inspects part positioning, weld height, gap size, and clamping status to guarantee optimized welding conditions and consistent quality.

In-Weld: Real-time monitoring of weld depth and fusion status ensures welds are neither too deep nor too shallow.

Post-Weld: The system verifies the surface integrity of the weld bead and records quality data to ensure every weld meets required specifications and industry standards.

💰 Achieve a Strong Return on Investment!

Companies using the LDD-700 for real-time weld monitoring have achieved over a 30% reduction in welding defects, resulting in substantial savings on scrap-related losses and downstream repair costs.

🚀 Extensively applied in battery production, automotive manufacturing, and various other high-precision industrial applications.!

Interested in learning more? Our team is ready to explore the right solution with you.

Contact Us